High Quality Stainless Steel Cable - Stainless Steel Wire Rope – Bangyi

High Quality Stainless Steel Cable - Stainless Steel Wire Rope – Bangyi Detail:

Product Description

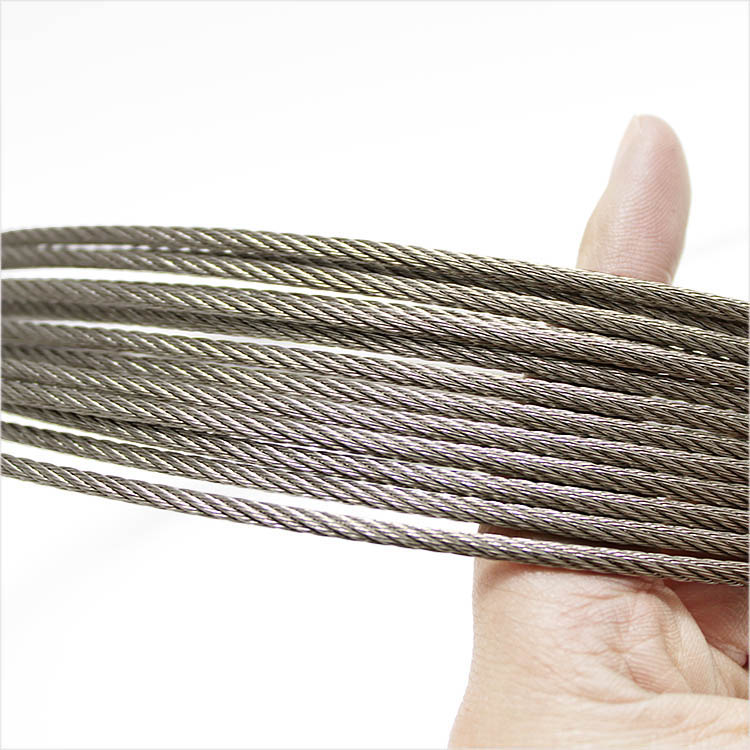

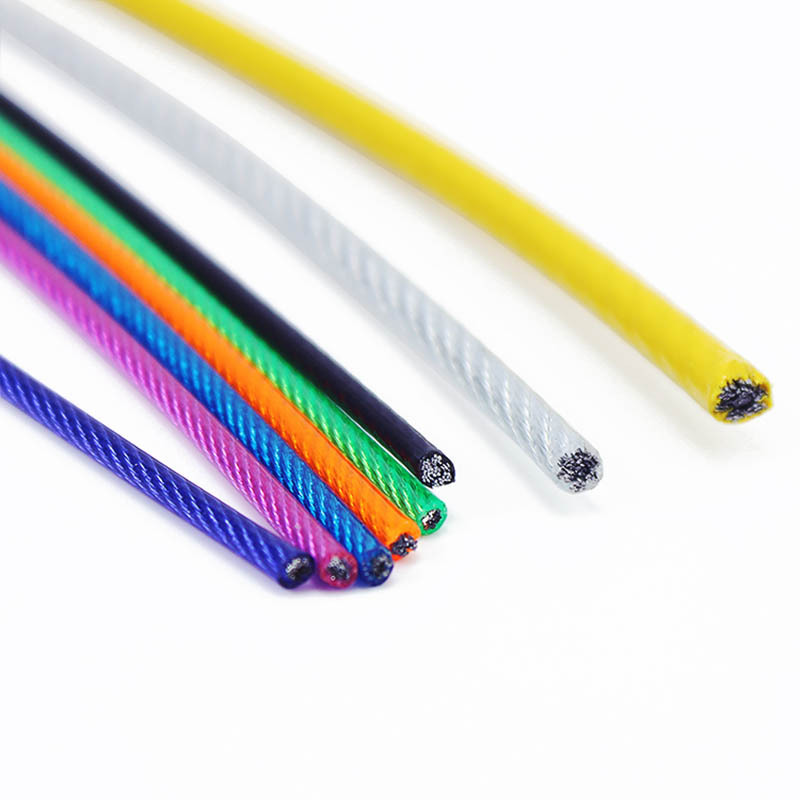

Stainless steel wire rope use high-quality AISI304, AISI316 as stainless steel raw materials. It has excellent corrosion resistance, high temperature resistance and low temperature resistance. It is widely used in petrochemical industry, aviation, automobile, fishing, building decoration and other industries. After electrolytic polishing, the stainless steel wire rope becomes bright and the corrosion resistance feature is greatly enhanced.

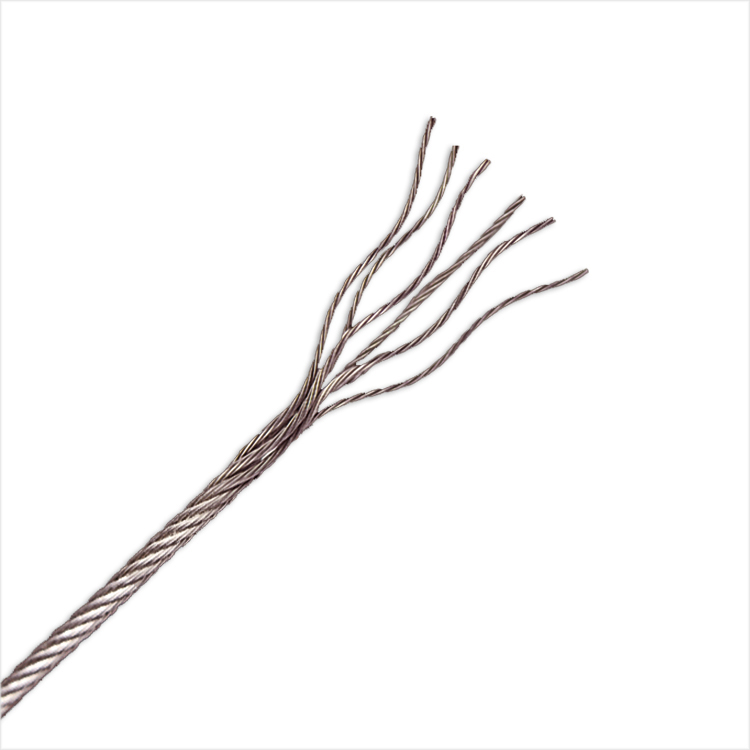

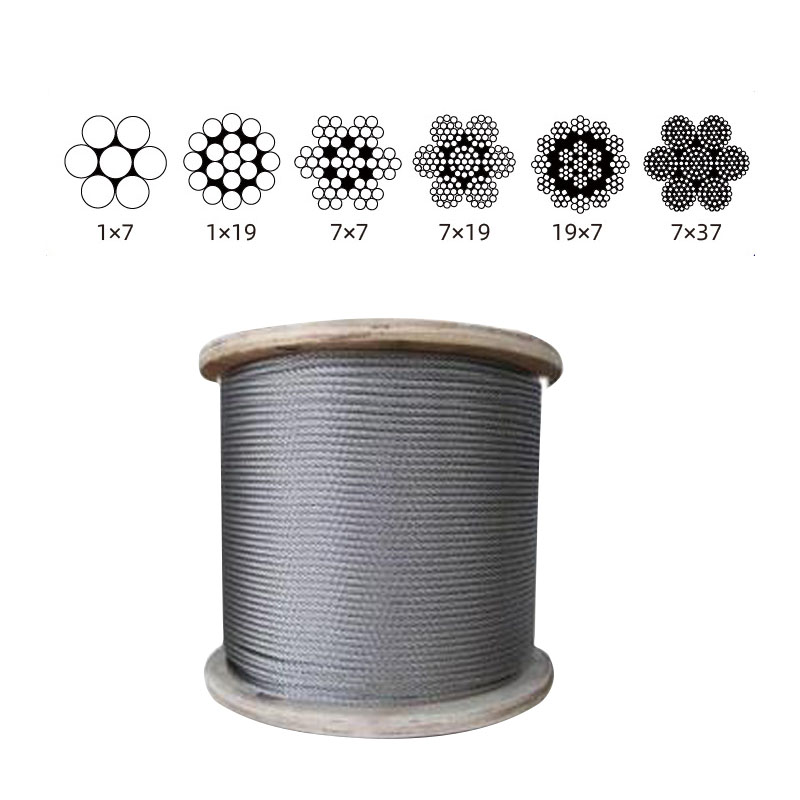

Stainless steel wire rope adopt fully automated production lines . The production process consists of wire drawing, stranding and closing. Wire drawing is to draw a thick steel wire rod into thin wire. Stranding is to synthesize wire into strands, and closing is to reshape strands into rope. After these three processes are completed, they undergo quality inspection, packaging, and finally become a finished product .

Stainless steel wire rope use high-quality AISI304, AISI316 stainless steel as raw materials. a helical wire bundle made of steel wires with mechanical properties and geometric dimensions that meet the requirements. steel wire rope is a rope that is twisted into strands from multiple layers of steel wire, and then a certain number of strands are twisted into a spiral with the core as the center. In material handling machinery, it is used for lifting, traction, tensioning and carrying. The steel wire rope has high strength, light weight, stable work, not easy to be broken suddenly, and reliable work. Stainless steel wire rope surface is smooth, highly polished, no burr, Good softness, heat and cold resistance, acid resistant, Good corrosion resistance(It resists pitting and corrosion by most chemicals, and is particular resistant to saltwater corrosion, Suitable for Marine/Saltwater Environment), high fatigue strength, and free from Lateral / longitudinal cracks, pits and marks etc.

Due to 316 stainless steel wire rope has stronger corrosion resistance, more widely used, However, the 304 stainless steel wire rope price is relatively cheap, When choosing stainless steel wire rope, 304 became the first choice, the stainless steel wire rope can be polished and heat treated to make the surface of the wire rope very bright and clean, greatly increasing the strength and corrosion resistance of the wire rope performance.

Stainless wire rope characterized by excellent surface quality, high-grade brightness, strong corrosion resistance, high tensile strength and fatigue resistance. high temperature resistance, high breaking force, long service life, durable, and many other characteristics of the industry, can be used transmit long-distance load,lifting, traction, tension and bearing. Light weight, It has high tensile strength, fatigue strength and impact toughness, use is safe and reliable, easy to carry and transport. Can be used for rigging, hoisting, push-pull, bearing and guying. Used in petroleum, chemical industry, elevators, lifting equipment, mining, automobiles, marine fishery, ,bridges, automobile, aircraft, railings, hardware light industry and other industries.

Specification

1X7

|

Diameter (mm) |

Approx. Weight (Kg/100m) |

EN12385-4 |

DIN3052 |

GB/T9944-2002 |

GB/T8918-3006 |

|||||

|

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

|||||||

|

1570/MM² |

1770/MM² |

1960/MM² |

1570/MM² |

1770/MM² |

|

1570/MM² |

1770/MM² |

|||

|

0.25 |

0.03 |

0.054 |

0.061 |

0.067 |

0.054 |

0.061 |

0.063 |

0.054 |

0.061 |

|

|

0.30 |

0.05 |

0.078 |

0.088 |

0.097 |

0.090 |

0.087 |

0.093 |

0.090 |

0.087 |

|

|

0.40 |

0.08 |

0.138 |

0.156 |

0.172 |

0.139 |

0.154 |

0.157 |

0.139 |

0.154 |

|

|

0.50 |

0.13 |

0.216 |

0.243 |

0.269 |

0.220 |

0.240 |

0.255 |

0.220 |

0.240 |

|

|

0.60 |

0.18 |

0.311 |

0.350 |

0.388 |

0.308 |

0.347 |

0.382 |

0.308 |

0.347 |

|

|

0.80 |

0.32 |

0.552 |

0.622 |

0.689 |

0.547 |

0.617 |

0.667 |

0.547 |

0.617 |

|

|

0.90 |

0.41 |

0.699 |

0.788 |

0.872 |

0.695 |

0.768 |

0.823 |

0.695 |

0.768 |

|

|

1.00 |

0.50 |

0.863 |

0.973 |

1.080 |

0.855 |

0.871 |

1.000 |

0.855 |

0.871 |

|

|

1.20 |

0.72 |

1.242 |

1.401 |

1.550 |

1.245 |

1.390 |

1.320 |

1.245 |

1.390 |

|

|

1.50 |

1.13 |

1.940 |

2.190 |

2.420 |

1.920 |

2.170 |

2.200 |

1.920 |

2.170 |

|

|

1.80 |

1.62 |

2.800 |

3.150 |

3.490 |

2.800 |

3.120 |

2.800 |

2.800 |

3.120 |

|

|

2.00 |

2.00 |

3.450 |

3.890 |

4.310 |

3.420 |

3.850 |

3.420 |

3.420 |

3.850 |

|

|

2.20 |

2.42 |

4.180 |

4.710 |

– |

4.120 |

4.690 |

4.120 |

4.120 |

4.690 |

|

|

2.50 |

3.13 |

5.390 |

6.080 |

– |

5.340 |

6.020 |

5.340 |

5.340 |

6.020 |

|

|

3.00 |

4.50 |

7.770 |

8.750 |

– |

7.690 |

8.670 |

7.690 |

7.690 |

8.670 |

|

|

4.00 |

8.00 |

13.80 |

– |

– |

13.70 |

– |

13.70 |

13.70 |

– |

|

|

5.00 |

12.50 |

21.60 |

– |

– |

21.40 |

– |

21.40 |

21.40 |

– |

|

|

6.00 |

18.00 |

31.10 |

– |

– |

30.80 |

– |

30.80 |

30.80 |

– |

|

7X7

|

Diameter (mm) |

Approx. Weight (Kg/100m) |

EN12385-4 |

DIN3052 |

GB/T9944-2002 |

GB/T8918-3006 |

|||||

|

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

|||||||

|

1570/MM² |

1770/MM² |

1960/MM² |

1570/MM² |

1770/MM² |

|

1570/MM² |

1770/MM² |

|||

|

0.8 |

0.26 |

0.390 |

0.440 |

0.440 |

0.390 |

0.440 |

0.461 |

0.360 |

0.410 |

|

|

0.9 |

0.33 |

0.495 |

0.560 |

0.560 |

0.495 |

0.560 |

0.539 |

0.460 |

0.520 |

|

|

1.0 |

0.41 |

0.610 |

0.690 |

0.690 |

0.610 |

0.690 |

0.637 |

0.570 |

0.640 |

|

|

1.2 |

0.58 |

0.880 |

0.990 |

0.990 |

0.880 |

0.990 |

1.200 |

0.820 |

0.920 |

|

|

1.5 |

0.91 |

1.370 |

1.550 |

1.550 |

1.370 |

1.550 |

1.670 |

1.280 |

1.440 |

|

|

1.8 |

1.32 |

1.970 |

2.230 |

2.230 |

1.970 |

2.230 |

2.250 |

1.840 |

2.070 |

|

|

2.0 |

1.62 |

2.440 |

2.540 |

2.540 |

2.440 |

2.540 |

2.940 |

2.080 |

2.350 |

|

|

2.2 |

1.97 |

2.960 |

3.300 |

3.300 |

2.960 |

3.300 |

3.400 |

2.800 |

3.120 |

|

|

2.5 |

2.54 |

3.180 |

4.290 |

4.290 |

3.810 |

4.290 |

4.350 |

3.540 |

4.000 |

|

|

3.0 |

3.65 |

5.480 |

5.720 |

5.720 |

5.480 |

5.710 |

6.370 |

4.690 |

5.280 |

|

|

4.0 |

6.50 |

9.750 |

10.20 |

10.20 |

9.750 |

10.20 |

9.510 |

8.330 |

9.400 |

|

|

5.0 |

10.15 |

15.23 |

15.90 |

15.90 |

15.23 |

22.90 |

14.70 |

13.00 |

14.60 |

|

|

6.0 |

14.62 |

21.90 |

22.90 |

22.90 |

21.90 |

40.60 |

18.60 |

18.70 |

21.10 |

|

|

8.0 |

25.98 |

39.00 |

40.70 |

40.70 |

36.10 |

63.50 |

40.60 |

33.30 |

37.60 |

|

|

10.0 |

40.60 |

60.90 |

63.50 |

63.50 |

56.30 |

91.50 |

57.10 |

52.10 |

58.70 |

|

1X19

|

Diameter (mm) |

Approx. Weight (Kg/100m) |

EN12385-4 |

DIN3052 |

GB/T9944-2002 |

GB/T8918-3006 |

|||||

|

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

|||||||

|

1570/MM² |

1770/MM² |

1960/MM² |

1570/MM² |

1770/MM² |

|

1570/MM² |

1770/MM² |

|||

|

0.4 |

0.08 |

0.132 |

0.149 |

0.165 |

0.132 |

0.150 |

0.170 |

0.132 |

0.150 |

|

|

0.5 |

0.13 |

0.206 |

0.232 |

0.257 |

0.210 |

0.235 |

0.240 |

0.210 |

0.235 |

|

|

0.6 |

0.18 |

0.297 |

0.335 |

0.370 |

0.297 |

0.332 |

0.343 |

0.297 |

0.332 |

|

|

0.8 |

0.32 |

0.530 |

0.590 |

0.660 |

0.530 |

0.590 |

0.617 |

0.530 |

0.590 |

|

|

1.0 |

0.50 |

0.820 |

0.930 |

1.030 |

0.825 |

0.930 |

0.950 |

0.825 |

0.930 |

|

|

1.2 |

0.72 |

1.190 |

1.340 |

1.480 |

1.200 |

1.350 |

1.270 |

1.200 |

1.350 |

|

|

1.5 |

1.13 |

1.850 |

2.090 |

2.320 |

1.860 |

2.090 |

2.250 |

1.860 |

2.090 |

|

|

1.8 |

1.62 |

2.670 |

3.010 |

3.330 |

2.680 |

3.010 |

3.100 |

2.680 |

3.010 |

|

|

2.0 |

2.00 |

3.300 |

3.720 |

4.120 |

3.300 |

3.720 |

3.820 |

3.300 |

3.720 |

|

|

2.2 |

2.42 |

3.990 |

4.500 |

– |

4.000 |

4.500 |

4.510 |

4.000 |

4.500 |

|

|

2.5 |

3.13 |

5.150 |

5.810 |

– |

5.150 |

5.800 |

5.580 |

5.150 |

5.800 |

|

|

3.0 |

4.50 |

7.420 |

8.360 |

– |

7.420 |

8.370 |

8.030 |

7.420 |

8.370 |

|

|

4.0 |

8.00 |

13.19 |

– |

– |

13.70 |

– |

13.90 |

13.70 |

– |

|

|

5.0 |

12.50 |

20.61 |

– |

– |

20.60 |

– |

21.00 |

20.60 |

– |

|

|

6.0 |

18.00 |

29.70 |

– |

– |

29.70 |

– |

30.40 |

29.70 |

– |

|

|

8.0 |

32.00 |

52.80 |

– |

– |

52.80 |

– |

52.80 |

52.80 |

– |

|

|

10.0 |

50.00 |

82.40 |

– |

– |

82.50 |

– |

82.50 |

82.50 |

– |

|

7X19

|

Diameter (mm) |

Approx. Weight (Kg/100m) |

EN12385-4 |

DIN3052 |

GB/T9944-2002 |

GB/T8918-3006 |

|||||

|

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

Min.Breaking Load (Kn) |

|||||||

|

1570/MM² |

1770/MM² |

1960/MM² |

1570/MM² |

1770/MM² |

|

1570/MM² |

1770/MM² |

|||

|

1.5 |

0.92 |

1.26 |

1.43 |

1.58 |

1.26 |

1.43 |

1.43 |

1.26 |

1.43 |

|

|

1.8 |

1.32 |

1.82 |

2.05 |

2.27 |

1.82 |

2.05 |

2.05 |

1.82 |

2.20 |

|

|

2.0 |

1.63 |

2.27 |

2.56 |

2.81 |

2.27 |

2.56 |

2.56 |

2.27 |

2.56 |

|

|

2.2 |

1.98 |

2.72 |

3.06 |

3.39 |

2.72 |

3.06 |

3.06 |

2.72 |

3.06 |

|

|

2.5 |

2.55 |

3.55 |

4.00 |

4.43 |

3.55 |

4.00 |

4.00 |

3.55 |

4.00 |

|

|

3.0 |

3.68 |

5.12 |

5.77 |

6.39 |

5.12 |

5.29 |

5.77 |

4.69 |

5.28 |

|

|

4.0 |

6.53 |

9.09 |

10.25 |

11.35 |

9.09 |

9.40 |

10.70 |

8.33 |

9.40 |

|

|

5.0 |

10.21 |

14.21 |

16.02 |

17.74 |

14.21 |

21.20 |

17.40 |

13.00 |

14.60 |

|

|

6.0 |

14.70 |

20.50 |

23.10 |

25.50 |

20.50 |

28.20 |

23.50 |

18.70 |

21.10 |

|

|

8.0 |

26.14 |

36.40 |

41.00 |

45.40 |

33.30 |

37.60 |

40.10 |

33.30 |

37.60 |

|

|

10.0 |

40.84 |

56.80 |

64.10 |

71.00 |

52.10 |

58.80 |

56.80 |

52.10 |

58.70 |

|

Product detail pictures:

Related Product Guide:

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for High Quality Stainless Steel Cable - Stainless Steel Wire Rope – Bangyi , The product will supply to all over the world, such as: Los Angeles, Portugal, Danish, Now we are sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We are ready to share win-win corporation.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

Related PRODUCTS

-

E-mail

-

Phone

-

Whatsapp

whatsapp

-

Wechat

Wechat